Category

- 5% OFF

- ALUMINUM

- ART & DECO

- BAG

- CARE & HEALTH

- COMMERCIAL SERVICE

- COOKING TOOLS

- ENGINE

- FESTIVITY SUPPLIES

- GARDENING

- GENERAL DIET

- HOME SECURITY

- JEWELRY

- MACHINERY

- MUSIC INSTRUMENT

- PERSONAL PROTECTIVE

- PREFABRICATED HOUSE

- PROJECTOR SCREEN

- SCHOOL

- SCHOOL SUPPLIES

- Scooter

- SPORT

- TECHNOLOGIES HIGH-TECH

- TOOLS & MATERIALS

- Non classé

- ANIMALS

- BATHROOM

- BEAUTY

- BICYCLE

- BOOK

- CARS

- CHILD

- COMPUTER

- CONSTRUCTION MATERIALS

- DIAMOND

- DIAMOND|GOLD

- ELECTRICAL SUPPLY

- EYEWEAR

- FESTIVITIES COSTUMES

- GAME

- GARDEN DECORATIONS

- GOLD

- HIGH-TECH FURNITURE & ACCESSORIES

- HOME

- INTERIOR DECORATIONS

- KALIS TRACE PRODUCTS

- KGK PRODUCTS

- LIGHTING and LIGHT

- MEDICAL DEVICE|TOOLS and EQUIPMENT

- MEN

- MOTOR

- MOTOR|CARS

- NAUTICAL

- OFFICE and SCHOOL SUPPLIES

- OPTICAL INSTRUMENT

- PAINTINGS

- PAPER PACKAGING

- RENEWABLE ENERGY

- SEX TOYS

- SIGNAGE

- SMOKING ACCESSORIES

- SPORTS EQUIPMENT

- TELEPHONE

- TEXTILE

- WOMEN

Detailed Images

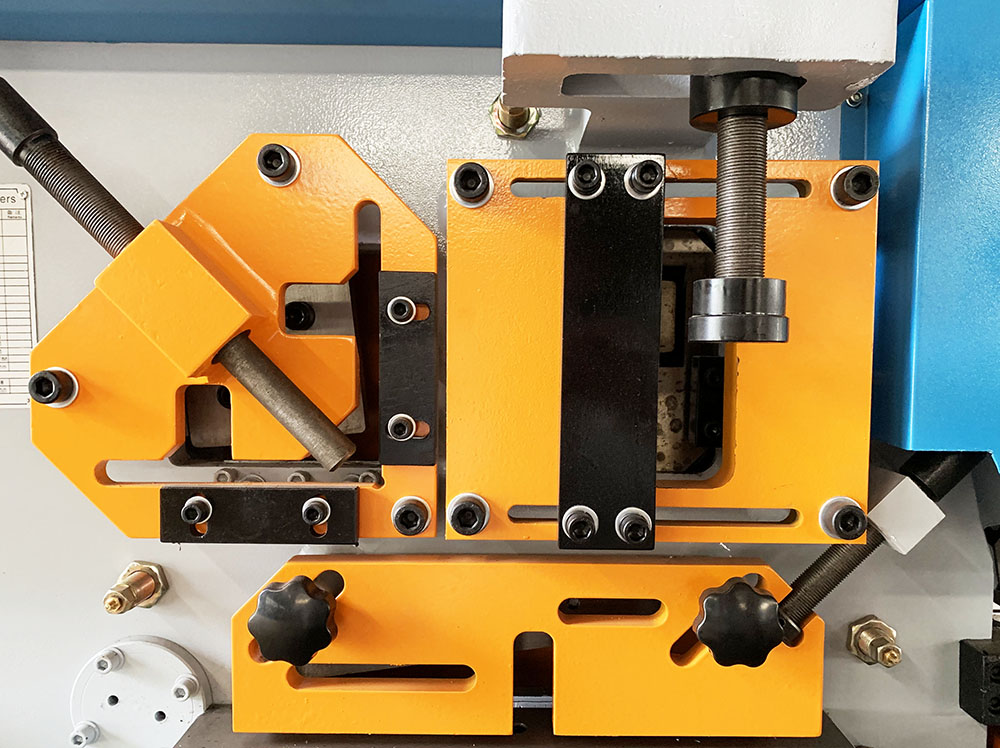

* Positioning ruler on the worktable can control the cutting shape and cutting length with higher accuracy

* Machine can cut small flat sheets , this function can be used as shearing machine .

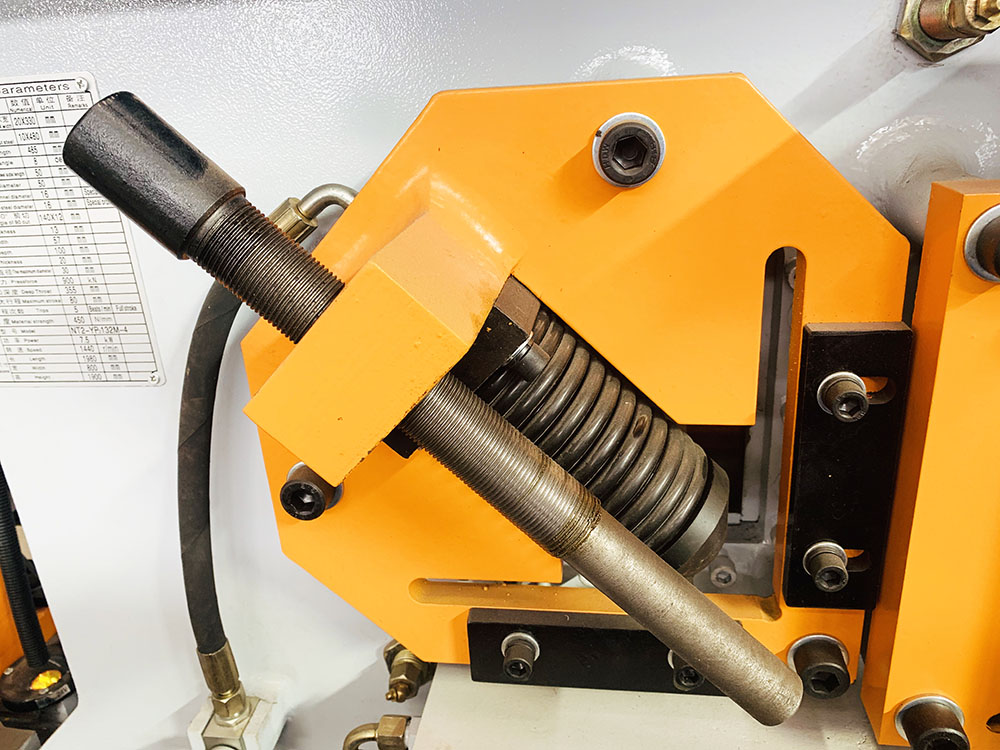

* The quantity and size of the round or square holes can be customized according to customer’ s requirements .

* lt share the same working

position with round

* Machine can cut any size of angle

steel whose length is smaller than

its Max. capacity

* Hydraulic Angle steel fixing device is

optional.

The unique design of die shear part enables the interlock safety protection of angel steel and flat steel processing shear electrical appliances,ensuring the maxium safwety of operator.

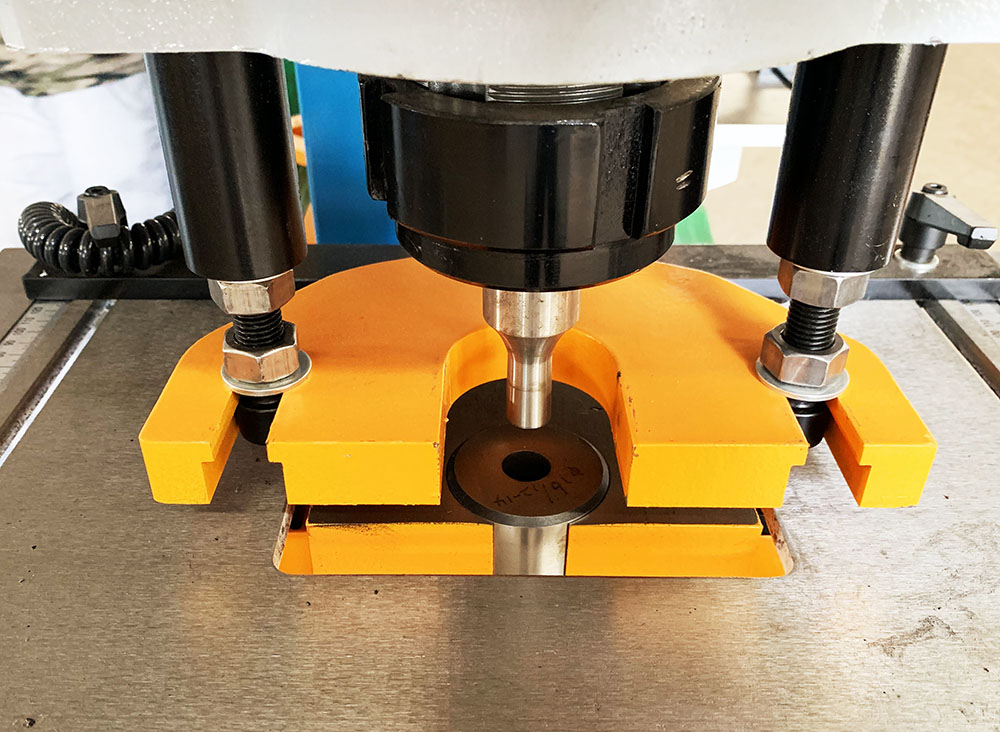

Punching Station

Measure Ruler

Measure ruler for know the size and more

accurations

|

NO.

|

Item

|

Manufacturer

|

Remarks

|

|

1

|

Electrics

|

Schneider – France

|

Standard

|

|

2

|

Main Motor

|

Siemens – Beide

|

|

|

3

|

Oil pump

|

SUNNY- USA

|

|

|

4

|

Valve block

|

Rexroth – Germany

|

|

|

5

|

Pedal switch

|

KACON – South Korea

|

|

|

6

|

Wind-cooler for oil

|

China

|

|

|

7

|

Sealing ring

|

Parker-USA

|

|

|

8

|

Oil pipe connector

|

High – pressure hose-Germany

|

|

|

9

|

Safety guard

|

Durmapress Self-Made

|

|

|

10

|

Manual stopper positioning

|

Durmapress Self-Made

|

Optional

|

|

11

|

Electric stopper positioning

|

Durmapress Self-Made

|

|

|

12

|

Automatic holding system ( Manual & Automatic)

|

Durmapress Self-Made

|

|

|

13

|

Infrared ray positioning ( Punching position )

|

China

|

|

|

14

|

Tandem (punching part and shearing part can be operated separately at the same time)

|

Durmapress Self-Made

|

Standard Components :

* A set of angle steel blade

* A set of shearing plate blade

* A set of notching blade

* 2 independent hydraulic piston rods and foot-pedal allows two people operating at the same time

* More efficient stroke-control functions of piston rod Central lubricating systeMotor-driven rear stopper

* Lighting devices for work

stations . For other dies and blades , customers need to order and pay additionally

| COLOR | Blue, Gray, Yellow |

|---|---|

| GIFT OPTION | NO, YES |

Related products

-

SMC Type AC1010~5010 Series

26.99$ – 69.50$Select optionsCondition: New Warranty: 6 Months Applicable Industries: Manufacturing Plant, Machinery Repair Shops Weight (KG): 1 Showroom Location: None Video outgoing-inspection: Provided Machinery Test Report: Provided Marketing Type: Air Source Treatment Unit Type: Source Treatment Unit, Air Source Treatment Unit Place of Origin: CALIFORNIA Brand Name: KSRJ Material: Carton Product name: AC1010~5010 factory supply pneumatic air …

-

-

DELEM DA66T MB8 200T 3200 CNC Press Brake

11,965.00$ – 11,969.50$Select optionsCNC Press Brake The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, …

-

Sheet Metal Plate Bending Machine

43,588.00$ – 43,592.50$Select options* New EU streamlined design. * The whole frame of the press brake adopt integrated welding, and by tempering to eliminate the internal stress. * The press brake frame adopt shot blast to remove rust and sprayed with anti-rust treatment. * The frame is formed by the imported CNC three-dimensional machining center in one process, …