Category

- 5% OFF

- ALUMINUM

- ART & DECO

- BAG

- CARE & HEALTH

- COMMERCIAL SERVICE

- COOKING TOOLS

- ENGINE

- FESTIVITY SUPPLIES

- GARDENING

- GENERAL DIET

- HOME SECURITY

- JEWELRY

- MACHINERY

- MUSIC INSTRUMENT

- PERSONAL PROTECTIVE

- PREFABRICATED HOUSE

- PROJECTOR SCREEN

- SCHOOL

- SCHOOL SUPPLIES

- Scooter

- SPORT

- TECHNOLOGIES HIGH-TECH

- TOOLS & MATERIALS

- Non classé

- ANIMALS

- BATHROOM

- BEAUTY

- BICYCLE

- BOOK

- CARS

- CHILD

- COMPUTER

- CONSTRUCTION MATERIALS

- DIAMOND

- DIAMOND|GOLD

- ELECTRICAL SUPPLY

- EYEWEAR

- FESTIVITIES COSTUMES

- GAME

- GARDEN DECORATIONS

- GOLD

- HIGH-TECH FURNITURE & ACCESSORIES

- HOME

- INTERIOR DECORATIONS

- KALIS TRACE PRODUCTS

- KGK PRODUCTS

- LIGHTING and LIGHT

- MEDICAL DEVICE|TOOLS and EQUIPMENT

- MEN

- MOTOR

- MOTOR|CARS

- NAUTICAL

- OFFICE and SCHOOL SUPPLIES

- OPTICAL INSTRUMENT

- PAINTINGS

- PAPER PACKAGING

- RENEWABLE ENERGY

- SEX TOYS

- SIGNAGE

- SMOKING ACCESSORIES

- SPORTS EQUIPMENT

- TELEPHONE

- TEXTILE

- WOMEN

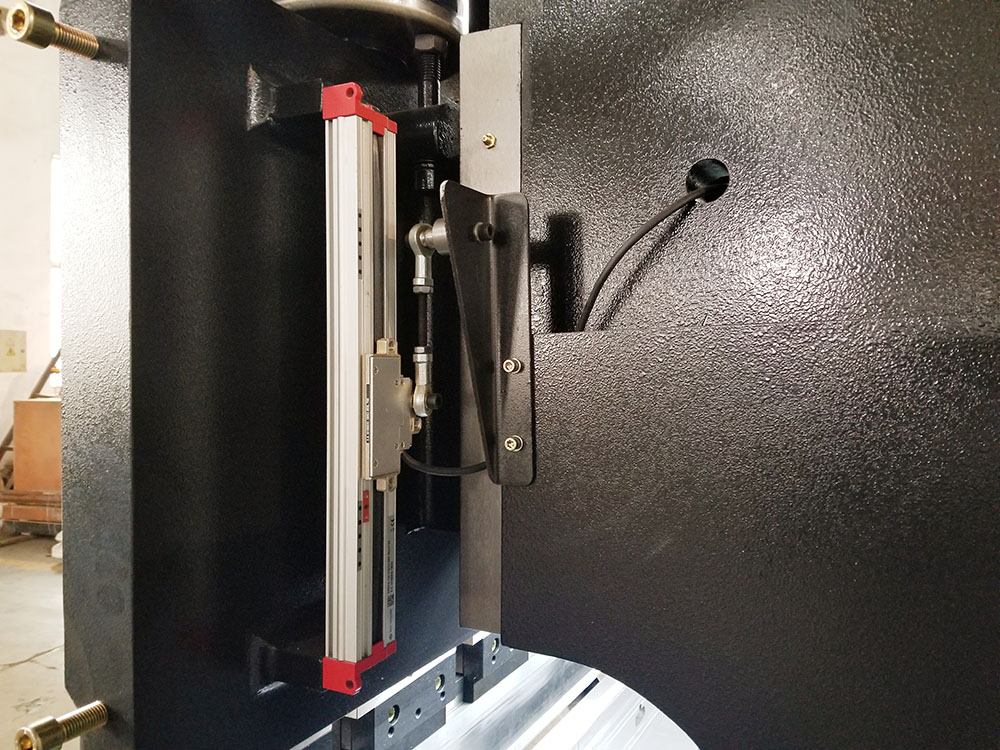

DELEM DA66T MB8 200T 3200 CNC Press Brake

11,965.00$ – 11,969.50$

CNC Press Brake

2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

3. Using international brand parts and cnc.

4. Visual operating system,easy operation,convenient,multi-functions and practical.

5. All parts are produced by cnc produce center,according to standard drawing.

6. High executive force,high standard and high professional machine assembled team.

7. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

8. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation.

9. Providing comprehensive bending program for all press brake,shearing machine user.

10.Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

11.Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.

12.Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

13.The similarity of images and shipping machine can reach 99.5%.

14.In time fast delivery.

|

Model

|

MB8 200T 3200

|

||

|

Pressing force

|

2000

|

KN

|

|

|

Working length

|

3050

|

MM

|

|

|

Distance between uprights

|

2600

|

MM

|

|

|

Stroke

|

250

|

MM

|

|

|

Distance table/ram

|

485

|

MM

|

|

|

Gap

|

400

|

MM

|

|

|

Table width

|

200

|

MM

|

|

|

Apprach speed

|

100

|

MM/S

|

|

|

Working speed

|

11

|

MM/S

|

|

|

Return speed

|

120

|

MM/S

|

|

|

Motor

|

22

|

KW

|

|

|

Volume of oil tank

|

550

|

L

|

|

|

Overall Dimension

|

3800*1900*2800

|

MM

|

|

Main Configuration

DA66T CNC Controller

Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Automatic Mechanical compensation

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

Safety Equipment:

Safety Standards(2006/42/EC)

1.EN 12622:2009+a1:2003

2.EN ISO 12100:20110

3.EN 60204-1:2006+A1:2009

| GIFT OPTION | NO, YES |

|---|

Related products

-

Performance 1500W Tube Fiber Laser

21,285.00$ – 21,289.50$Select optionsitem value Application LASER CUTTING Applicable Material Metal, sheet metal Condition New Laser Type Fiber Laser Cutting Area 6000*220 Cutting Speed 80m/min CNC or Not Yes Cooling Mode Air Cooling Control Software Cypcut Warranty of core components 5 years Mode of Operation Pulsed Configuration 3-axis

-

Roof ridge tiles building materials

9,147.00$ – 9,151.50$Select optionsApplicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Food & Beverage Shops Showroom Location: Kenya, Colombia, Kazakhstan, Kyrgyzstan, Uzbekistan, Malaysia Condition: New Type: Tile Forming Machine Tile Type: Colored Glaze Steel, Colored Glaze Steel Use: ROOF Production Capacity: 15m/Min Place of Origin: Anhui, China Brand Name: Durmapress …

-

-