Category

- 5% OFF

- ALUMINUM

- ART & DECO

- BAG

- CARE & HEALTH

- COMMERCIAL SERVICE

- COOKING TOOLS

- ENGINE

- FESTIVITY SUPPLIES

- GARDENING

- GENERAL DIET

- HOME SECURITY

- JEWELRY

- MACHINERY

- MUSIC INSTRUMENT

- PERSONAL PROTECTIVE

- PREFABRICATED HOUSE

- PROJECTOR SCREEN

- SCHOOL

- SCHOOL SUPPLIES

- Scooter

- SPORT

- TECHNOLOGIES HIGH-TECH

- TOOLS & MATERIALS

- Non classé

- ANIMALS

- BATHROOM

- BEAUTY

- BICYCLE

- BOOK

- CARS

- CHILD

- COMPUTER

- CONSTRUCTION MATERIALS

- DIAMOND

- DIAMOND|GOLD

- ELECTRICAL SUPPLY

- EYEWEAR

- FESTIVITIES COSTUMES

- GAME

- GARDEN DECORATIONS

- GOLD

- HIGH-TECH FURNITURE & ACCESSORIES

- HOME

- INTERIOR DECORATIONS

- KALIS TRACE PRODUCTS

- KGK PRODUCTS

- LIGHTING and LIGHT

- MEDICAL DEVICE|TOOLS and EQUIPMENT

- MEN

- MOTOR

- MOTOR|CARS

- NAUTICAL

- OFFICE and SCHOOL SUPPLIES

- OPTICAL INSTRUMENT

- PAINTINGS

- PAPER PACKAGING

- RENEWABLE ENERGY

- ROBOT

- SEX TOYS

- SIGNAGE

- SMOKING ACCESSORIES

- SPORTS EQUIPMENT

- TELEPHONE

- TEXTILE

- WOMEN

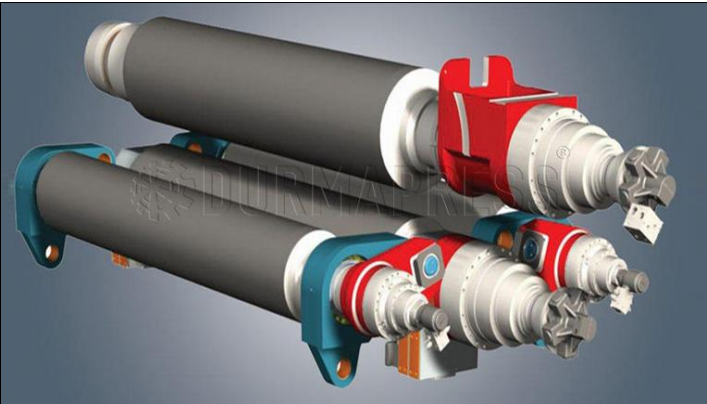

Rolling Machine

* W11 series plate rolling machine with mechanical drive.When take away work pieces,upper roller can be separated.Upon request,wecan install kinds of side wheels to bend different types metal sheet.

* W12 series rolling machine with four rollers adopt upper roller rotary mechanical drive,lower and side roller fluctuation drive,electric concentrated control opreation system.This machine can complete pre-bending and pipe shaped rolling for one material feeding,arc or moderate taper shaped material can be pre-bend in this machine with minimized residual straight margin and high work efficiency,it also can do the work of the approximate leveling for matal plate to be processed.The machine equipped with NC System contyrol,improve automation level.It is widely used in petroleum,chemical boiler,shipbuilding,metal structure and mechanical manufacturing industry.

Detailed Images

PLC Control System

*HMI(Human Machine interface)intellgent operation.Self-compensating,single operate,high effeciency,safe and convenient.

*Many models for choice,economic numberical control madel

*A PLC control system ensure the machine bottom and lateral rolls operate synchronously.Up to eight steps can be playgrammed eith the touchsceem.

*Passed CE cetification to meet the needs of overseas markets.

W11 Series 3 Roller Plate Rolling Machine

|

Model

|

Max.thickness of plate(mm)

|

Max.width of plate(mm)

|

Plate yeild limit (Mpa)

|

Rolling speed(mm–1)

|

Min dia of plate in full load(mm)

|

Dia. of upper/lower roller(mm)

|

Space between of two lower rollers(mm)

|

Main moter(kw) power

|

mimension(L*W*H)(mm)

|

|

W11-6*1500

|

6

|

1500

|

265

|

7.16

|

380

|

180/160

|

210

|

5.5

|

3310*1210*1330

|

|

W11-6*2000

|

6

|

2000

|

265

|

7.16

|

380

|

180/160

|

220

|

5.5

|

3810*1210*1330

|

|

W11-6*2500

|

6

|

2500

|

265

|

7.16

|

500

|

190/170

|

260

|

7.5

|

4310*1210*1330

|

|

W11-6*3200

|

6

|

3200

|

265

|

6.45

|

500

|

240/200

|

310

|

11

|

5220*1400*1200

|

|

W11-8*2000

|

8

|

2000

|

265

|

7.16

|

450

|

190/170

|

260

|

7.5

|

3810*1210*1330

|

|

W11-8*2500

|

8

|

2500

|

265

|

6.46

|

500

|

240/200

|

310

|

11

|

4500*1420*1610

|

|

W11-12*2000

|

12

|

2000

|

265

|

5

|

500

|

240/200

|

310

|

11

|

4050*1420*1610

|

|

W11-12*2500

|

12

|

2500

|

265

|

5

|

750

|

260/220

|

330

|

11

|

5000*1500*1300

|

|

W11-12*3000

|

12

|

3000

|

265

|

5

|

650

|

280/240

|

360

|

15

|

5500*1500*1300

|

|

W11-16*2000

|

16

|

2000

|

265

|

5

|

750

|

260/220

|

330

|

11

|

4500*1500*1300

|

|

W11-16*2500

|

16

|

2500

|

265

|

5

|

750

|

280/240

|

360

|

15

|

5000*1500*1300

|

|

W11-16*3200

|

16

|

3200

|

265

|

5

|

900

|

340/280

|

440

|

22

|

6300*1600*1900

|

|

W11-20*2000

|

20

|

2000

|

265

|

5

|

750

|

280/240

|

360

|

15

|

4500*1500*1300

|

|

W11-20*2500

|

20

|

2500

|

265

|

5

|

850

|

340/280

|

440

|

30

|

5600*1600*1900

|

|

W11-25*2000

|

25

|

2000

|

265

|

5

|

850

|

340/280

|

440

|

30

|

5100*1600*1900

|

|

W11-25*2500

|

25

|

2500

|

265

|

4.5

|

900

|

380/300

|

490

|

37

|

6000*4600*2150

|

|

W11-30*2000

|

30

|

2000

|

265

|

4.5

|

900

|

380/300

|

490

|

37

|

5500*1460*2150

|

|

W11-30*2500

|

30

|

2500

|

265

|

4.34

|

1100

|

460/380

|

600

|

45

|

6900*2300*2800

|

|

W11-30*3000

|

30

|

3000

|

265

|

5

|

1200

|

460/400

|

600

|

45

|

7400*2300*2800

|

|

W11-30*3200

|

30

|

3200

|

265

|

5

|

1200

|

500/400

|

600

|

45

|

7600*2300*2600

|

|

W11-40*2000

|

40

|

2000

|

265

|

5

|

1200

|

480/400

|

600

|

45

|

6400*2300*2800

|

Features:

Nowadays, plate bending has become more and more a CNC-supported operation. DURMAPRESS ® was the first manufacturer to use CNC on four roll-plate bending machines specifically designed for bending circular cans for applications like wind tower production and also complex shapes for applications like tank production. DURMAPRESS ® is continuously developing innovative numerical controls for three-roll production, specifically indicated for the production of thick cones or heavy duty cans.

W12 Series 4 Roller Plate CNC Rolling Machine

|

Model

|

Max. Bending Thickness (mm)

|

Max. width of plate (mm)

|

Rolling speed(m/min)

|

Pre-Bending Thickness (mm)

|

Min dia. of plate in full load (mm)

|

Dia. of upper/lower /sider roller (mm))

|

Main moter (KW)

|

Dimension L*W*H(mm)

|

|

W12-8*2000

|

8

|

2000

|

6.1

|

6

|

700

|

280/260/180

|

11

|

8300*1400*1760

|

|

W12-8*2500

|

8

|

2500

|

6.1

|

6

|

750

|

300/260/180

|

15

|

6100*2000*2070

|

|

W12-12*2000

|

12

|

2000

|

5.5

|

10

|

700

|

300/280/230

|

15

|

5600*2000*2070

|

|

W12-12*2500

|

12

|

2500

|

5.5

|

10

|

750

|

340/300/260

|

22

|

6300*2000*1800

|

|

W12-12*2000

|

12

|

2000

|

4

|

10

|

850

|

380/340/280

|

30

|

7600*2000*2150

|

|

W12-16*4000

|

16

|

4000

|

5.5

|

12

|

750

|

340/300/260

|

22

|

5800*2000*1800

|

|

W12-16*2500

|

16

|

2500

|

6.5

|

12

|

850

|

350/320/280

|

30

|

6810*2000*1870

|

|

W12-20*2000

|

20

|

2000

|

6.5

|

16

|

850

|

350/320/280

|

30

|

6000*2000*1850

|

|

W12-20*2500

|

20

|

2500

|

6.5

|

16

|

1000

|

400/380/320

|

37

|

6850*2000*2070

|

|

W12-20*3000

|

20

|

3000

|

4.5

|

16

|

1100

|

450/420/350

|

45

|

7310*2100*2200

|

|

W12-25*2000

|

25

|

2000

|

6.5

|

22

|

1000

|

400/380/320

|

37

|

6300*2300*2070

|

|

W12-25*2500

|

25

|

2500

|

5

|

22

|

1100

|

450/420/350

|

45

|

8000*2600*2100

|

|

W12-25*3000

|

25

|

3000

|

5

|

22

|

1150

|

480/460/380

|

55

|

9000*3200*2500

|

|

W12-25*4000

|

25

|

4000

|

4

|

22

|

1200

|

540/500/450

|

63

|

10100*3500*2900

|

|

W12-30*2000

|

30

|

2000

|

5

|

25

|

1100

|

450/420/350

|

45

|

7500*2600*2500

|

|

W12-30*2500

|

30

|

2500

|

4.5

|

25

|

1150

|

480/460/380

|

55

|

8400*2590*2600

|

|

W12-30*3000

|

30

|

3000

|

4

|

25

|

1300

|

560/520/420

|

60

|

9200*3500*2900

|

|

W12-30*4000

|

30

|

4000

|

4

|

25

|

1500

|

650/600/480

|

60

|

10200*3500*2900

|

|

W12-40*2000

|

40

|

2000

|

4.5

|

36

|

1200

|

520/500/400

|

45

|

8200*3000*2500

|

|

W12-40*2500

|

40

|

2500

|

4

|

36

|

1300

|

560/520/420

|

60

|

8700*3500*2900

|

Description of Main Components :

This machine is reliable and effective. The parallelism of the side rolls is controlled by a torsion bar system that connects to both ends of the side roll, eliminating the disadvantage of extra encoders and special hydraulic balancing valves. The two central rolls are driven by hydraulic motors and high efficiency planetary gearboxes coupled directly on the rolls. The Durmapress solution, with rolls assembled on sealed bearings and without secondary components, reduces the dispersions of the applied force generated by the frictions of the various components (typical in synchronization systems used in Press Brake).

|

Name

|

Details

|

Manufacture

|

Remarks

|

|

Hydraulic System

|

*Pump Station

|

ChangYuan , China

|

Options : Sunny

USA

|

|

*Valve

|

Yuken , Japan

|

/

|

|

|

Control Device

|

*Low Voltage Apparatus

|

Siemens, Germany

|

/

|

|

Drive Device

|

*Motor

|

Hanzhu , Ningbo

|

/

|

|

Side Frame and Chassis

|

*Material

|

Q235

|

Standard

|

|

*Techniques

|

Side Roller Lift cylinder

material for 45# forgings ,

quenching and tempering

heat treatment HB217-255

|

/

|

|

|

Working Roller

|

*Material

|

42CrMo

|

Standard

|

|

*Techniques

|

Forging piece go through

rough machining then

quenching and tempering

treatment at HB241-280

|

/

|

|

|

Electrical Control System

|

*Touchwin from China

|

Durmapress

|

/

|

|

Sealings

|

*NOK

|

Japan

|

/

|

|

Bearing

|

*WFD

|

China

|

/

|

|

PLC Encoder

|

*Omron

|

Japan

|

/

|

|

Other Electrical Parts

|

*Simens

|

German

|

/

|

Optional Components

* Top and lateral support rack for big diameter * Ground and polished rolls for special job

* Safety cable

* Fan cooled or water cooled

* Cone bending device

| GIFT OPTION | NO, YES |

|---|

SKU: N/A

Category: MACHINERY

Related products

-

Sheet Metal Plate Bending Machine

43,588.00$ – 43,592.50$Select options This product has multiple variants. The options may be chosen on the product page* New EU streamlined design. * The whole frame of the press brake adopt integrated welding, and by tempering to eliminate the internal stress. * The press brake frame adopt shot blast to remove rust and sprayed with anti-rust treatment. * The frame is formed by the imported CNC three-dimensional machining center in one process, …

-

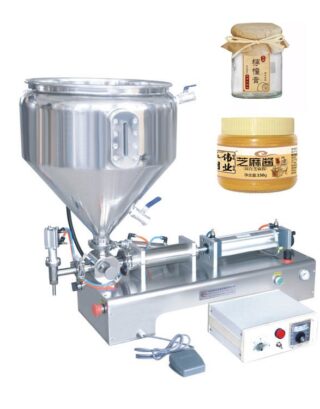

Multifunctional Juice Tea Milk

2,500.00$ – 2,504.50$Select options This product has multiple variants. The options may be chosen on the product page -

3kw Cnc IpgRaycus Laser 3015

60,112.00$ – 60,116.50$Select options This product has multiple variants. The options may be chosen on the product pageName Quantity Brand Brand of Country 3000W Laser 1 set JPT China Special Precision Cutting Head for Fiber 1 set WSX/RAYTOOLS China Precise Rack 3 sets YYC Taiwan, China Reducer (Including Gears) 3 sets SHIMPO Japan High Speed Servo Motor and Drive 4 sets Fuji Japan High Precision Linear Guide Rail (Tool) 3 sets HIWIN …

-

Multifunctional Plastic Pickle Single

2,478.00$ – 2,482.50$Select options This product has multiple variants. The options may be chosen on the product page